Mounted Packer / Harrow System and Shank Mount Packers

The Best in Precision Packing

The K-Hart Series IV onrow packer system is a packer system for direct seeding or conventional seeding. It is designed for the customer that wants the best precision on-row seed packing.

K-Hart Series IV airseeder packers have features and benefits that no other packer system in the industry has to offer. We challenge you to find any other add-on packer system on the market that will out pack us!

Our distinguished Features start with the way we uniquely mount onto the back of the cultivator frame:

- Massive parallelogram trailing arms bolt to the back of the cultivator frame. These tension spring adjustable arms ensure that just enough pressure is applied to the packer wheels. Our parallel linkage arms move straight up and down for a total of 12″ of vertical travel.

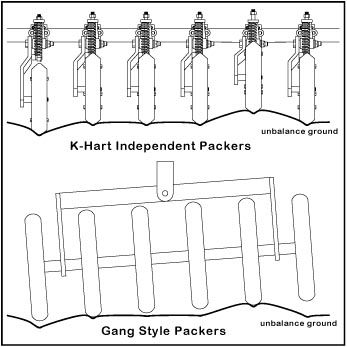

- Each packer assembly has its own spring for the uneven seedbeds or obstacle clearance. If one packer assembly rides on a high ridge or bounces over a rock or pile of straw, it does not affect the performance of the other packers on the trailing arm. Each packer assembly can travel up to a total of 6″ in height. Our system is not like other packers on the market that have 6 to 10 packers attached to a central axle gang (gang-style packers) and tend to all lift off the ground when one packer hits a rock or uneven seedbed. See illustrated diagram.

- Each spring-loaded packer arm also has its own swivel bracket to allow the packer assembly to pivot from side to side. When turning with your air seeder in the ground, the swivel brackets allow the packer to swivel from side to side and stay in the seeded run. Other packers on the market that can not swivel can skew the seed run, ridge the soil or may even flip upside down.

- An optional walking axle can be installed between a set of packer wheels allowing each packer wheel contact on the ground 100% of the time. The adjustable width spacing (7″-12″) of our walking axle packer assembly allows the packer to walk up and down 3 inches. To explain differently, one packer could pack a seed run that was up to 3 inches higher than the other packer, yet both packer wheels would still have ground contact. We also have a single-wheel packer assembly option available.

- We have a wide range of packer styles. All packer wheels are a semi-pneumatic rubber of the highest quality. Check out our various profiles featured below.

- Optional 2-row harrows. The harrow option will help to level out uneven seedbeds due to high soil disturbance. A single row harrow option is also available.

- We have adapters to be used on Bourgault quick-change arms. Should you have Bourgault quick-change harrows or Bourgault quick-change packers, we have an adapter that fits onto their arm saving you the cost of purchasing our parallelogram trailing arms. It’s as simple as installing our packers with our adapter to hook up to their arm.

- Save money on fuel! Packing can be a one-pass packing operation completed while you seed. Further, this is an efficient packer system requiring less than 1/2 HP per foot to pull. Economically sensible.

When one packer is raised by an obstacle, the other stays on the ground – as shown.

Package A configuration option:

- 2 packer wheels on one straight through axle on a spring-loaded arm assembly.

- If one packer lifts going over a rock or lumps of straw, it will lift the other packer wheel.

- Assembly pivots from side to side to help keep packing in your seed row when turning around trees, headlands, slough, etc.

Package B configuration option:

- 2 packer wheels with a walking axle and an adjustable packer spacing on a spring-loaded arm assembly.

- One packer can go over a rock or piles of straw without affecting the other packer. Also can adjust the spacing of the wheels by moving walking axle.

- Assembly pivots from side to side to help keep packing in your seed row when turning around trees, headlands, slough, etc.

Package C configuration option:

- 1 packer per spring-loaded arm assembly.

- Assembly pivots from side to side to help keep packing in your seed row when turning around trees, headlands, slough, etc.

Shank Mount Packer Assembly

- Spring-loaded shank mount assemblies do not swivel from side to side

- Not recommended for cultivator spacings closer than 10″ because of the potential of reducing straw flow through the cultivator.

- Some limitations with seed openers can be used without interfering with mount of packer.

K-Hart Independent Packers vs Gang Style Packers

K-Hart Independent Packers:

- No matter how uneven your seed bed, K-Hart independent packers will stay packing 100% of the time, which helps to ensure even germination.

- Each K-Hart packer features a swivel bracket which better enables packing each seed row, when turning around sloughs, trees or headlands.

- K-Hart packers will out pack any other mounted airseeder packer on the market.

Gang Style Packers:

- Gang packers ride on the high seed rows, bounce over rocks and straw bunches. It doesn’t allow all packers to touch the ground, contributing to uneven germination.

- Gang packers do not follow the seed rows when turning by sloughs, trees and headlands.

- Cultivator weight is required to get all wheels in the gang packer closer to the ground, sacrificing cultivator performance.